FAQ on firing and storage

If you are the person in charge of a traditional clay studio, and wish to have both types of clay available, both could be fired in the same kiln. Load the single fire glazed in one area with the bisque glazed. Consider dry storage of scraps see below and how much power and time can be saved. There are

eco friendly tips also.

No need to baby things dry and other conveniences that could make life easier and less frustrating. I even started my beginners with paperclay until they got the knack of proper joins (first attempt to attach a handle and it breaks? test before fire- go fix it- save a ton of fuel that way too!)- then advance to intermediate to try traditional clay which they will have to baby- slow dry and fire- but should know about...., and then pick what they like after.

🔥 Firing PaPerClay in electric kilns🔌🔌🔌 Myths vs Evidence So Far

1 Kiln Vent ♨️ first hours of fire is recommended for waxes, sulfur and off gases escaping from the traditional clay minerals and organics. The smoke/smell time 450F for both wax or embedded pulp in normal paperclay happens the first hours before the kiln air gets superheated it is relatively 🆒 during gradual heat up of the ware.

2 Pre-red heat 🆒 pre-red heat smoke out two hours of "paper" pulp embedded in a paperclay didn't shorten the life of the kiln heating elements. Embedded pulp vaporizes gone hours before bisque temps but research is needed.

What shortens the metallic elements life is after hours of power on they succeed in superheating the air inside a kiln to red hot ♨️ air (ie gas.) Elements are vulnerable and function at best without needing extra fuel- paper or plastic.

Too much fuel can be added so a "reduction" atmosphere (pyrolysis) follows- ♨️ this kind of kiln air reacts and degrades surface coils of your elements and it causes all kinds chemistry change in ware- raku glaze an example of (This is why avoid add or fire crumpled newspaper or combustibles (banana peels etc) in electric kilns designed for oxidation- they burn at red heat for sure and this hot smoke degrades your elements more.)

Artificial petrochemical sourced man made fiber like nylon in clays and or paperclays.... burnout is proving to add toxins and pollution of air than anyone planned for another reason for kiln vent.

3 Reduction kiln atmosphere of black smoke carrying tar, CO and soot in a red hot kiln) forms from too much fuel not enough oxygen.

Electric kilns 🔌 are not designed for reduction fires but they are designed for red heat oxidation and a kiln vent. Some schools teach it's ok to fire crumpled newsprint inside a handbuilt work- but its not advised.

Single glaze fire skips the bisque 🔥 since water based glaze is absorbed in green dry paperclay. Just let the pot dry between quick dip, spray or brush. If you wait too long the water will penetrate and soften the paperclay. It will start to deform. Test test first until you know what you have.

CAUTION Beware fire retardant spray on treated dry fluff pulp

Avoid adding so called recycled dry pulp insulation (such as a building material) treated with any fire retardant which is law in some countries- in a your home batch paperclay- fire retardant boron etc in fire generates TOXIC foul fumes and extends the burnout smoking time about 6 hours all the hours to the red heat. It seemed like a good idea until.... toxic smoke continued to well beyond bisque heat--nope a hidden ingredient was the cause.

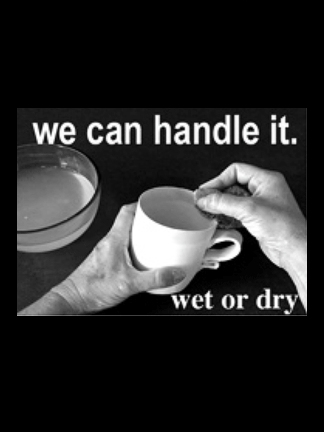

Safety and Storage Dry Preferred over Wet

Use fresh batch. Aging not needed because the pulp brings moisture deep inside clay during mix.

Store scraps of paperclay dry not wet! Wet time varies depending on the base clay used and the temperature- weeks to 3-6 month or years.

(Or, of it must be wet- double or triple bag it to avoid finding a heavy dried brick you can't cut through. The good news is you can chisel it as if it is stone into a sculpture if theres enough pulp in there you can glaze and fire it too.)

Avoid making a stink storing wet

Unlike most porcelains, clays with lots of impurities (- tan, brown, red --- iron, organic matter) and warm weather may start to grow microbes in weeks- molds can grow too- on the outside which can be scraped off the edges. It depends- so test first if you have an allergy- only use fresh batch very fresh like in a few days of mix- no time for mold to grow. Pictures are in my book.

Storing wet clay in muck bucket even not paperclay can cause microbes fungi, algae of various sorts and some smell over time. Temperature can matter and the kind of local water can also make a difference in the brew. Mold- mildew can grow on any wet clay over time- paperclay or not- so anyone with this concern or skin sensitivity must mix and use paperclay fresh and let it dry within a few days so theres no time for and of these microbes to grow. Also avoid bleach as disinfectant in anything. I know my teachers used to use a few drops.... but I have learned it's not wise for skin.

In contrast, paperclay porcelains hardly grow any microbes in 3 months or longer- even years...some of them stored wet double bagged but. The iron bearing baseclays its not as good. No problem just something to know.

To store dry - I slice remainder of a pugged or wedged leftover hunks/soft chunks up - to bread like tiles-to let dry. They reconstitute quickly in bucket of water, pour off extra and you have it!.

Storing box or bags of dried scraps are light weight and easy to move compared to wet barrels of water-slurry as in traditional clay studios. I just make a note of what type of clay/cone rating it is

learn more.

Dry paperclay scrap whispers: To hear, dip in water and LISTEN for a lovely little sound of water soaking in- that lasts a few seconds. This is how I can tell which scrap is a paperclay and which is not a paperclay.